Pumps

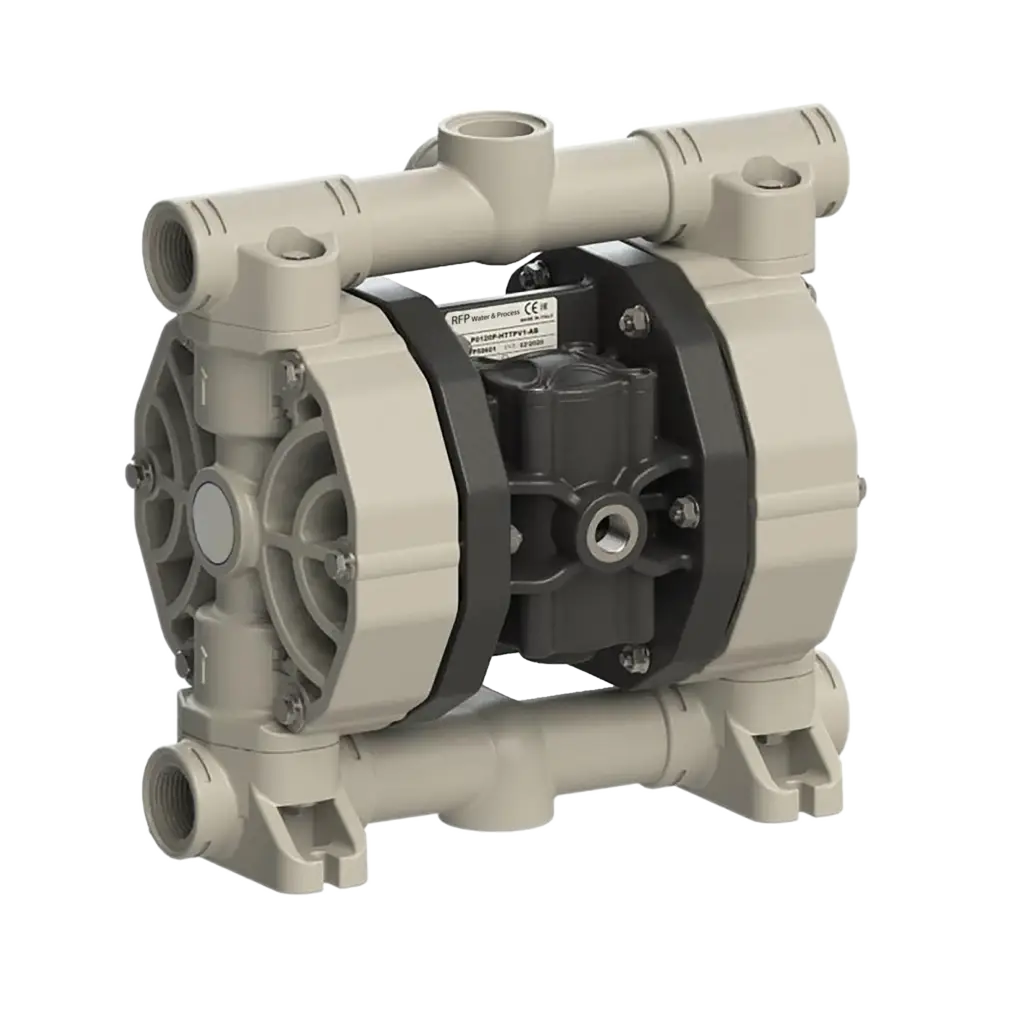

Double diaphragm pumps, or also known as pneumatic pumps, are mechanical devices used to move fluids. They are particularly useful for transporting corrosive, viscous liquids or those containing suspended solids.

They operate through a flexible membrane that moves back and forth, creating pressure that sucks in fluid on one side and pushes it out on the other. This system is controlled by compressed air intake regulation, which can be manual or automatic.

The diaphragm pumps we supply are of PP, PVDF, ALUMINUM and AISI 316.

Benefits

- Dry running without damaging the pump or system: design without dynamic blindfolds

- Dry self-priming up to 6 meters: works in lift-vacuum applications

- Handling liquids with solid particles: ideal for abrasive and viscous media

- Fully submersible: can be completely submerged according to fluid compatibility.

Applications

- Food industry

- Mining industry

- Ceramic industry

- Petrochemical industry

- Construction industry

- Beer industry

- Cosmetic industry

- Pharmaceutical industry

- Textile industry

- Agriculture

- Water treatment

A peristaltic pump is a machine that applies the principle of peristalsis, where the construction along the tube, due to its elasticity, generates pressure fluctuations.

The tube, which must resist crushing deformation as much as possible due to elastic rather than plastic deformation, and is a fundamental component of the pump.

It is the elasticity that allows the tube to recover its original size and guarantee fluid pressure and suction capacity.

Tubing for peristaltic pumps is available in a variety of materials, including Hypalon, NR, NBR, Norprene, Silicone, EPDM, Pharmed and Tygon.

Benefits

- They run dry, are self-priming and reversible.

- They operate without valves or mechanical seals, which often cause breakdowns or malfunctions in other types of pumps.

- They can be applied to pumping abrasive sludge, sludge or viscous fluids, in cases that require considerable suction capacity, or that require maximum delicacy in transferring the fluid to maintain its original characteristics.

- They can be used in explosive environments and provide great dosing accuracy.

- Due to their constructive simplicity and reduced maintenance time, they save on expenses, as the only component that wears out is the rubber tube, which can be replaced quickly and easily.

Applications

- Water treatment

- Paper industry

- Cosmetic industry

- Pharmaceutical industry

Horizontal centrifugal pumps are high-performance pumps operated by a direct drive electric motor for rapid fluid transfer and drainage, with flow rates ranging from 6 to 40 m³/h.

The special design of the semi-open impeller allows continuous pumping even with dirty fluids, with an apparent viscosity of up to 500 cps and small suspended solids.

The semi-open impeller is mounted on the pump shaft which is integral to the electric motor drive shaft.

Centrifugal pumps have the option of being supplied with mechanical packing or magnetic drive.

Benefits

- High Performance: they are designed to offer high efficiency in the transfer and rapid drainage of fluids, with flow rates ranging from 6 to 40 m³/h, meeting various operational needs.

- Semi-Open Impeller Design: The semi-open impeller allows continuous pumping of even dirty fluids with apparent viscosity up to 500 cps and small suspended solids, ensuring versatility and reliability in difficult applications.

- Wide Temperature Range: Pumps operate efficiently over a wide temperature range, from -20°C to +95°C, offering flexibility in a variety of operating environments.

- Versatile Electric Motor: Available with electric motors from 0.37 kW to 5.5 kW, the pumps can be adapted to different power needs and energy requirements.

- If the magnetic drive version is selected: the pump has no leakage points, allowing it to be used in applications that require greater tightness.

Applications

- Food industry

- Mining industry

- Ceramic industry

- Petrochemical industry

- Construction industry

- Beer industry

- Cosmetic industry

- Pharmaceutical industry

- Textile industry

- Agriculture

- Water treatment

Sugarcane pumps are lightweight, practical and powerful devices for economical and safe filling and are designed for intermittent, not continuous, use.

Different pump tubes of our drum pumps for different media are interchangeable and can be used with the same electric or pneumatic motor.

Benefits

- Light and Practical: NEPTUNE pumps are light and easy to handle, making them easy to transport and operate in different work locations.

- High Power: These pumps are powerful, allowing efficient filling and transfer of low to medium viscosity fluids, whether neutral or aggressive.

- Interchangeable Pump Tubes: The different pump tubes are interchangeable and compatible with the same electric or pneumatic motor, allowing flexibility in handling different types of media.

- Safety and Economy: NEPTUNE pumps are designed to provide economical and safe filling and transfer of fluids, minimizing the risk of spills and accidents.

Applications

- Paper industry

- Cosmetic industry

- Pharmaceutical industry

- Water treatment